Additive manufacturing

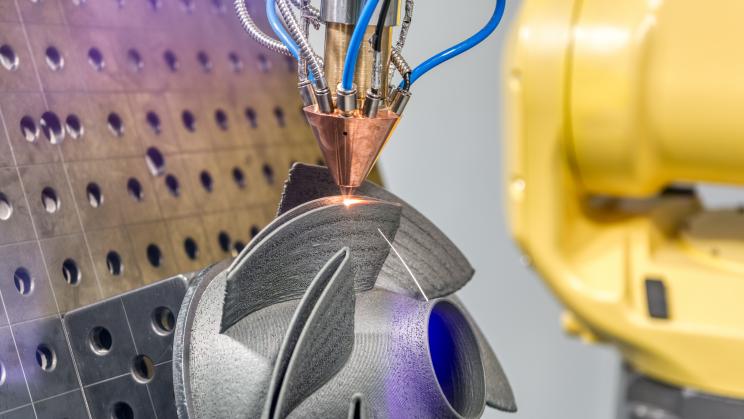

Additive manufacturing (AM)—also referred to as 3D printing—describes a category of automated manufacturing techniques. These manufacturing techniques can be used to build an object of virtually any shape or form, based on a digital build file, by depositing and fusing layers of material. AM enables the production of more complex objects as well as new performance characteristics in products, for example, precise cooling channels in rocket motors, lightweight bionic designs or new forms of artificial tissue.

While early AM techniques hail from the 1970s, following more recent leaps in the technology linked to their digitization and automation, AM machines and designs are now grouped among a host of technological innovations that the World Economic Forum calls the ‘fourth industrial revolution’. Furthermore AM has increasing military and dual-use applications and has had an impact on the development of products in the aerospace sector and the chemical, biological and nuclear (CBN) fields. This development has placed it firmly on the agenda of non-proliferation regimes, including the multilateral export control regimes.

SIPRI’s work on AM focuses on its impact on the development and proliferation of conventional weapons, CBN weapons and their delivery systems—including missiles. It also explores the challenges that the decentralization and digitization of advanced production capabilities pose, in particular for export controls and other governance approaches.